One-stop lubrication solution | Discover the way to smoothness | Infomak

PRODUCT PARAMETERS

Description

Introduction to Engine Oil

Engine lubricants are key liquids used to lubricate the internal components of the engines of motor vehicles such as cars and trucks. It not only reduces friction between metal parts, but also cleans the inside of the engine, helps cool it and prevents corrosion. Lubricant additives are chemicals added to further improve the performance of lubricants. They can enhance the oil’s anti-oxidation, anti-wear, clean dispersibility and viscosity-temperature characteristics.

Features of Engine Oil

Excellent thermal stability: Able to remain stable under high temperature conditions and not easy to decompose.

Excellent oxidation stability: Prevents lubricants from deteriorating and extends service life.

Good low-temperature fluidity: ensures that the engine is fully lubricated even when starting cold.

Efficient cleaning ability: prevents the formation of deposits and varnish, keeping the engine clean.

Increased anti-wear ability: reduces wear between key components, improves engine efficiency and life.

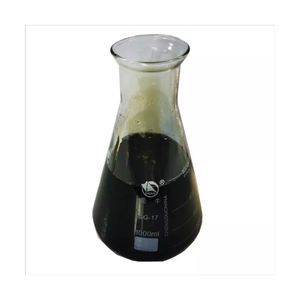

(High Quality Waste Industrial Oil Refining Distiller Black Lubricants Engine Oil Recycle Base Oil Set)

Specification of High Quality Waste Industrial Oil Refining Distiller Black Lubricants Engine Oil Recycle Base Oil Set

This equipment transforms used industrial oils right into useful base oils. It manages waste lubes, engine oils, and similar fluids. The procedure gets rid of contaminations and recuperates functional base stock. This base oil is necessary for making new lubricants once again.

The distiller unit is developed strong. It makes use of thick commonplace steel. This ensures lengthy life under challenging conditions. The system consists of a vertical distillation tower. This tower effectively divides the excellent oil from impurities. A condenser system cools down the vapor back right into fluid oil. Security is vital. The system consists of pressure assesses and security shutoffs. These screen procedures and protect against problems. The layout prioritizes secure, reputable efficiency.

Conventional ability frequently begins around 500 liters per set. Larger versions exist for larger needs. The device typically works on common electrical power. Power demands depend on the size you pick. Installment is simple. Operators need fundamental training to run it efficiently. Maintenance involves regular checks and cleaning. This maintains everything working efficiently.

The essential advantage is changing waste right into profit. You save significant cash on new base oil purchases. Recycling onsite cuts disposal fees and transportation expenses. It lowers environmental effect sensibly. The outcome base oil satisfies top quality requirements. It’s suitable for blending new lubes or other industrial usages. This machine uses a smart option for oil administration. It offers a solid return on investment over time.

(High Quality Waste Industrial Oil Refining Distiller Black Lubricants Engine Oil Recycle Base Oil Set)

Applications of High Quality Waste Industrial Oil Refining Distiller Black Lubricants Engine Oil Recycle Base Oil Set

This maker turns unclean utilized oils right into important base oils. Factories and workshops generate lots of waste oil. This consists of utilized engine oil from trucks and makers. It includes filthy lubricating substances from hefty equipment. It includes metalworking fluids and hydraulic oils. This waste oil is a trouble. Dumping it harms the setting. Disposal prices cash. This distiller solves these issues.

It cleans the waste oil. The procedure removes impurities. It removes water, sludge, and acids. It eliminates other pollutants. The outcome is tidy base oil. This base oil is top quality. It meets sector criteria. This base oil is valuable. It is the structure for making new lubricating substances.

Manufacturing facilities use this recycled base oil. They mix it with ingredients. This makes brand-new engine oil. It makes brand-new commercial lubricating substances. It makes transmission liquids. It makes gear oils. Reusing saves substantial costs. Buying brand-new base oil is costly. Recycling cuts that expenditure. It also decreases waste disposal fees.

This equipment helps the setting. It quits waste oil contaminating land and water. Reusing saves resources. It reduces the requirement for crude oil. This makes operations a lot more sustainable. Companies meet ecological regulations easier. They boost their eco-friendly credentials.

The distiller takes care of several oil types. It services utilized motor oil. It works with commercial lubricating substances. It services hydraulic liquids. It deals with metalworking coolants. This adaptability is essential. Various businesses have various waste streams. The device adapts. It supplies a dependable resource of clean base oil. This base oil sustains lubricating substance manufacturing. It maintains machinery running efficiently. It secures beneficial devices.

Company Introduction

Welcome to Infomak, Infomak is dedicated to the technology development of special oil additives, combined the Technology of nanomaterials developed dry lubricant and oil additives two series. Our products can significantly improve the performance of lubricating oil, improve energy efficiency, effectively protect the lubrication device and extend the oil change cycle, which can satisfy the lubrication oil constantly upgrading for high-end engine oil additives.

If you have any questions, please feel free to contact us(nanotrun@yahoo.com).

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Waste Industrial Oil Refining Distiller Black Lubricants Engine Oil Recycle Base Oil Set

Here are 5 common questions about our High Quality Waste Industrial Oil Refining Distiller for Black Lubricants Engine Oil Recycle Base Oil Set:

What does this distiller do?

This machine cleans dirty waste oil. It takes used engine oil, industrial lubricants, or other black oils. It processes them. It makes clean, reusable base oil. This base oil is good quality. You can use it again or sell it.

How does the machine work?

It uses heat and vacuum distillation. The dirty oil goes into the system. It gets heated carefully. Different parts of the oil boil at different temperatures. The system separates the good base oil vapor. It cools this vapor down. You get clean liquid base oil. Bad parts get left behind.

What kind of waste oil can I use?

Use common waste oils. Engine oil from cars or trucks works. Industrial lubricants and hydraulic fluids are good. Transmission fluid is acceptable. The oil should not have water mixed in. Too much water causes problems. Remove water first for best results.

Is the base oil quality good?

Yes, the base oil quality is high. Our distiller uses precise temperature control. This ensures effective separation. The vacuum helps lower boiling points. This protects the oil. The output base oil meets standards. It’s suitable for reuse or blending.

Is the machine safe to operate?

Safety is important. The system includes key safety features. It has pressure and temperature gauges. These show conditions inside. Automatic pressure release valves are installed. These prevent dangerous build-up. Explosion-proof electrical parts are used. Proper operation training is essential. Always follow the safety manual.

(High Quality Waste Industrial Oil Refining Distiller Black Lubricants Engine Oil Recycle Base Oil Set)

REQUEST A QUOTE

RELATED PRODUCTS

2025Whole 5w30 Full Synthetic Engine Oils Automotive 5 Liter Motor Lubricant Oils With Low

Famous Cheap Sae 5L Car Lubricant Motor Engine Oil 0W-20 Fully Synthetic Oil

Factory Hot ing Used Engine Oil Lubricant for

5W40 Fully Synthetic Motor Oil Car Engine Lubricant European Version Imported 1L Engine Oil

Factory Whole SAE 50 Gas Diesel Engine Oil 20LTS Motor Oil CD/SF Engine Lubricant Oil for Passenger Cars Trucks Motorcycles